For decades, plywood and steel Shuttering have dominated concrete formwork — trusted, familiar, and widely used. But with rising timber costs, quality inconsistencies, and maintenance-heavy processes, the industry is beginning to question if tradition is holding it back.

Enter PAC® (Plastic Aluminium Composite) Shuttering Boards — a next-generation solution designed to outlast and outperform conventional materials. Yet, like any innovation, PAC® boards face skepticism: Are they strong enough? Cost-effective? Reliable on-site?

This guide clears the air. We’ll tackle and debunk the most common myths about PAC® boards — and show why they’re redefining durability, efficiency, and sustainability in modern construction.

First, What Exactly Are PAC® Shuttering Boards?

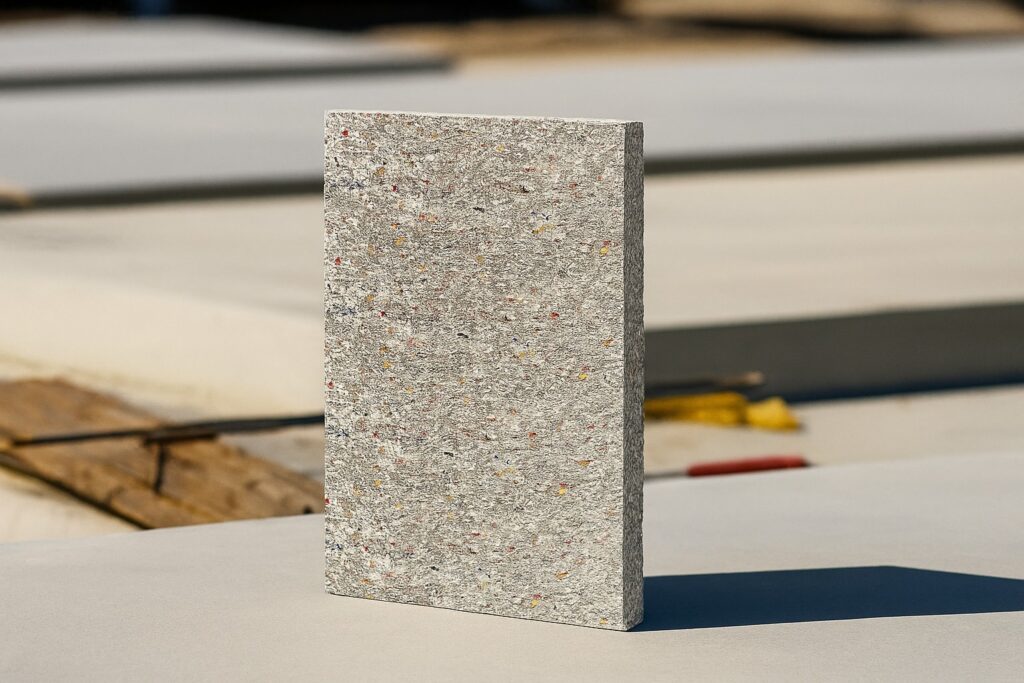

Before we tackle the myths, it’s essential to understand what a PAC® board is. It is not simply a sheet of plastic.

PAC® Shuttering Boards are high-strength, reusable construction boards made from a blend of industrial-grade plastic, aluminium oxide, and XLP metals. They’re designed to replace traditional shuttering sheets.

Myth vs. Reality: A Deep Dive into PAC® Boards

Let’s confront the common industry doubts one by one.

Myth 1: PAC® Boards are made from recycled plastic, so they must be weaker and less reliable than BWP plywood.

The Reality: PAC® Boards are not made from recycled or post-consumer plastic waste.

They are engineered using pre-consumer industrial-grade plastic — directly sourced from verified manufacturing industries.

This means the material is virgin in quality and consistency, not degraded or contaminated like recycled plastic. As a result, PAC® Boards deliver superior load-bearing capacity, dimensional stability, and a longer life span than BWP plywood — without swelling, cracking, or delamination.

Myth 2: The upfront cost is too high. Plywood is the cheaper option.

The Reality: Focusing solely on the initial purchase price is a short-sighted approach to project costing. The true financial metric is the “cost per use.” Let’s break it down with a simple scenario:

- Plywood: A standard BWP-grade shuttering plywood may cost ₹50–₹60/sq.ft. AND gives 5–10 uses. After that, it swells, bends, or breaks.

- PAC® Board: Our Board costs around ₹80/sq.ft. PAC® Standard Boards deliver 30–40 repetitions, and PAC® Premium Boards go beyond 60+ repetitions — without losing shape or strength.

When you compare lifespan, PAC® Boards easily save 3–5 times more money over the long run.In simple terms — you buy fewer boards, replace less often, and finish projects faster.

Myth 3: It will warp, melt, or become brittle in the extreme Indian climate.

The Reality: PAC® boards are specifically formulated for a wide range of climatic conditions, from the scorching heat of a Rajasthan summer to the humid, rainy season in Kerala. They have excellent UV stability, preventing them from becoming brittle under prolonged sun exposure. Furthermore, their low coefficient of thermal expansion means they don’t deform or warp significantly with temperature fluctuations. While a steel shutter can become dangerously hot to the touch and plywood can delaminate in cycles of heat and moisture, PAC® boards remain dimensionally stable, ensuring a consistent and reliable formwork system year-round.

Myth 4: Achieving a high-quality, smooth concrete finish is impossible.

The Reality: Quite the opposite. PAC® boards are known for their superior surface finish Traditional plywood absorbs moisture from fresh concrete, often leaving behind grain marks, uneven textures, and weaker surfaces that require costly plastering or grinding.

PAC® boards, on the other hand, have a non-absorbent, perfectly smooth surface that produces a clean, concrete finish straight from the formwork. For exposed concrete walls or ceilings, this means no additional finishing work — saving both time and money while elevating visual quality.

Myth 5: My crew can’t use their standard tools; we’d need special equipment.

The Reality: PAC® boards are designed for seamless integration into existing construction workflows. They can be easily cut, drilled, and fastened using the same saws, drills, nails, and screws that are used for plywood. There is no learning and no need to invest in specialized equipment. This ensures that the transition from wood to PAC® is smooth, efficient, and requires no additional training .

Myth 6: “Cleaning and maintaining the boards between uses must be a nightmare.”

The Reality: Unlike plywood or steel, concrete does not bond to the surface of PAC® boards. This means cleaning takes minutes, not hours — usually just a rinse with a high-pressure water jet. No scraping, sanding, or re-oiling required.

The result? Lower labor costs, quicker turnaround, and cleaner boards ready for the next pour — every time.

Myth 7: The surface is so smooth; isn’t it a slip hazard for workers?

The Reality: This is a valid safety question that demonstrates a deep understanding of site conditions. When handled, they offer adequate grip for manual transportation and installation. During formwork assembly, all standard safety protocols for working at height and on scaffolds should be followed, regardless of the shuttering material used. The material’s properties do not introduce any new, unmanageable on-site hazards.

Myth 8: It’s a niche product. It must be hard to source and get technical support.

The Reality: With established manufacturers like Rajratan Industries, PAC® Shuttering Boards are readily available across the country through a robust distribution network. Far from being a niche item, they are becoming the material of choice for major infrastructure projects. Reputable suppliers provide comprehensive technical support, including guidance on best practices for use, handling, and storage to help clients maximize the lifespan and ROI of their investment.

Conclusion: An Investment in a Smarter Future

By moving past outdated myths and embracing this engineered solution, you are not just buying a product. You are investing in efficiency, unmatched durability, superior quality, and a more profitable and sustainable way to build.

Ready to see the future of formwork for yourself? Contact Rajratan Industries today for a detailed project consultation, a personalized ROI calculation, or an on-site product demonstration.

- Phone: 0731 4045302

- Mobile: +91 96857 27927

- Email: info@rajratan.in